Types of Industrial Control Systems

Industrial Control Systems (ICS) play a critical role in the automation and control of various industrial processes and infrastructures, including manufacturing, power generation, and transportation systems. These systems are designed to monitor and control various processes, machinery, and equipment, ensuring efficient and safe operation. ICS can be broadly classified into two main categories: Programmable Logic Controllers (PLCs) and Distributed Control Systems (DCSs).

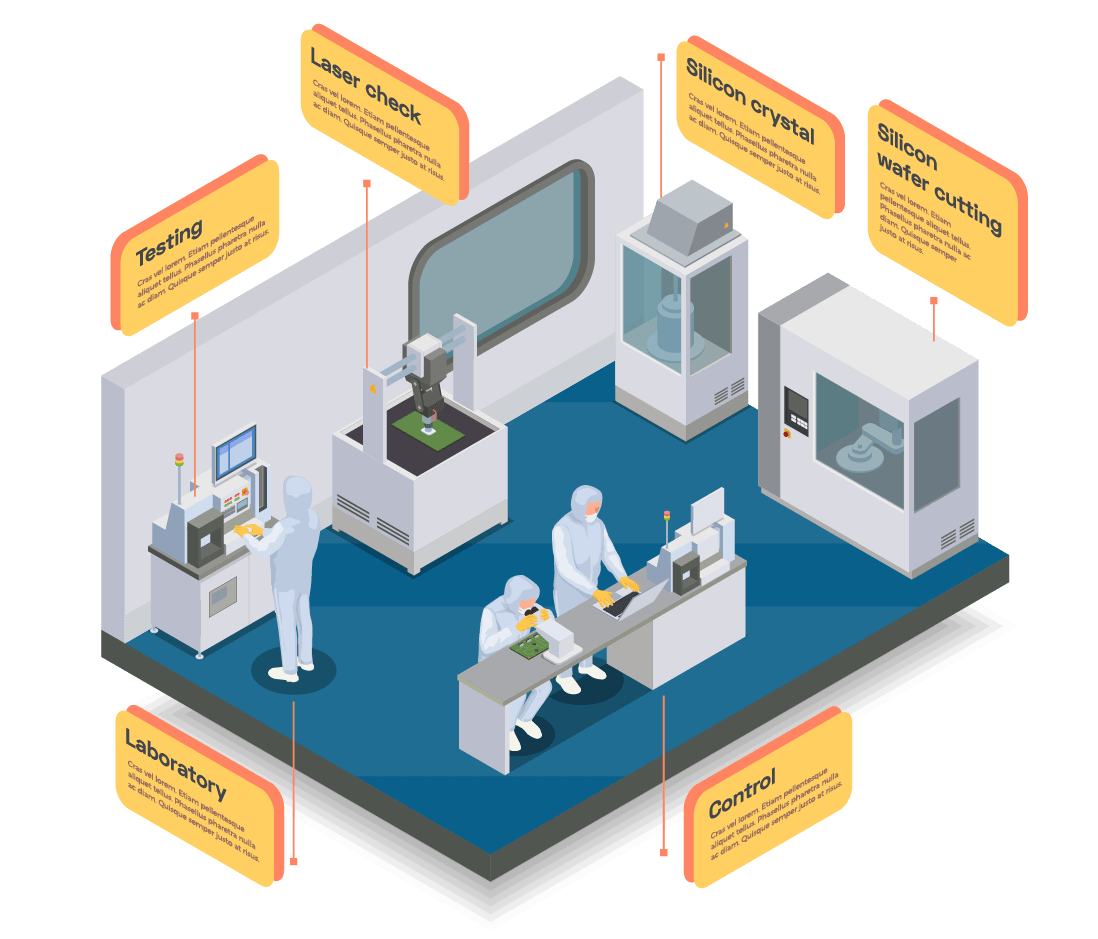

Programmable Logic Controllers (PLCs) are used in manufacturing and process control applications, where they control and monitor production processes. PLCs are designed to be rugged and reliable, and are often located on the factory floor in harsh industrial environments. They are used to control a wide range of machinery, from simple devices such as conveyor belts to complex production lines.

Distributed Control Systems (DCSs) are used in large-scale process control applications, such as power plants, water treatment facilities, and oil refineries. DCSs are typically located in control rooms and are used to monitor and control processes in real-time. They consist of a central computer and a network of remote I/O devices that communicate with the computer to exchange process data and control signals.